Loading... Please wait...

Loading... Please wait...- Contact

- wiggys@wiggys.com

- Home

- Why Lamilite?

Learn More

Recent Commentary

Subscribe to Wiggy's Newsletter » Receive updates about new products, specials, and learn about insulation technology

Why Lamilite Insulation?

The single most important component of any insulated product, be it a sleeping bag, parka, bib, snowsuit, booties or mittens, is the insulation inserted into these products. All insulated Wiggy's products have only one insulator: Lamilite.

Lamilite, which uses a continuous filament fiber called Climashield® by Harvest, CI, Inc. as its main component, is the best material developed thus far for use as insulation in sleeping bags or outerwear. I believe that our sleeping bags and extreme cold weather outerwear are so good that to purchase any other brand is a waste of money. To purchase a sleeping bag with any less quality could not only mean a very unpleasant camping trip, it could also mean your life. I say "your life" because I believe a sleeping bag is the most important piece of equipment you take into the field.

The functional difference that truly sets the Wiggy's Bag apart from the rest is its insulation! Lamilite possesses an extraordinary quality that helps contain the flow of heat that your own body generates. The key to Lamilite is its ability to allow the body's own thermostat to function efficiently.

Lamilite is Lofty Insulation

The more loft surrounding your body, the more difficult it is for your body heat to escape.

Lamilite is Lightweight

The lighter the weight of the insulation the lighter the weight of the finished product be it a sleeping bag or garment.

Lamilite is Very Soft

Put on a Lamilite parka and you will automatically think it is a down filled parka. The same holds true for our sleeping bags. They surround the body much the way a down bag does, filling in or draping closed around the body. This eliminates heat loss from convection. Conductive heat loss is reduced significantly. The fiber used for Lamilite is not densely packed into our products (as will be explained later) therefore, the loss of heat via conduction is minimized.

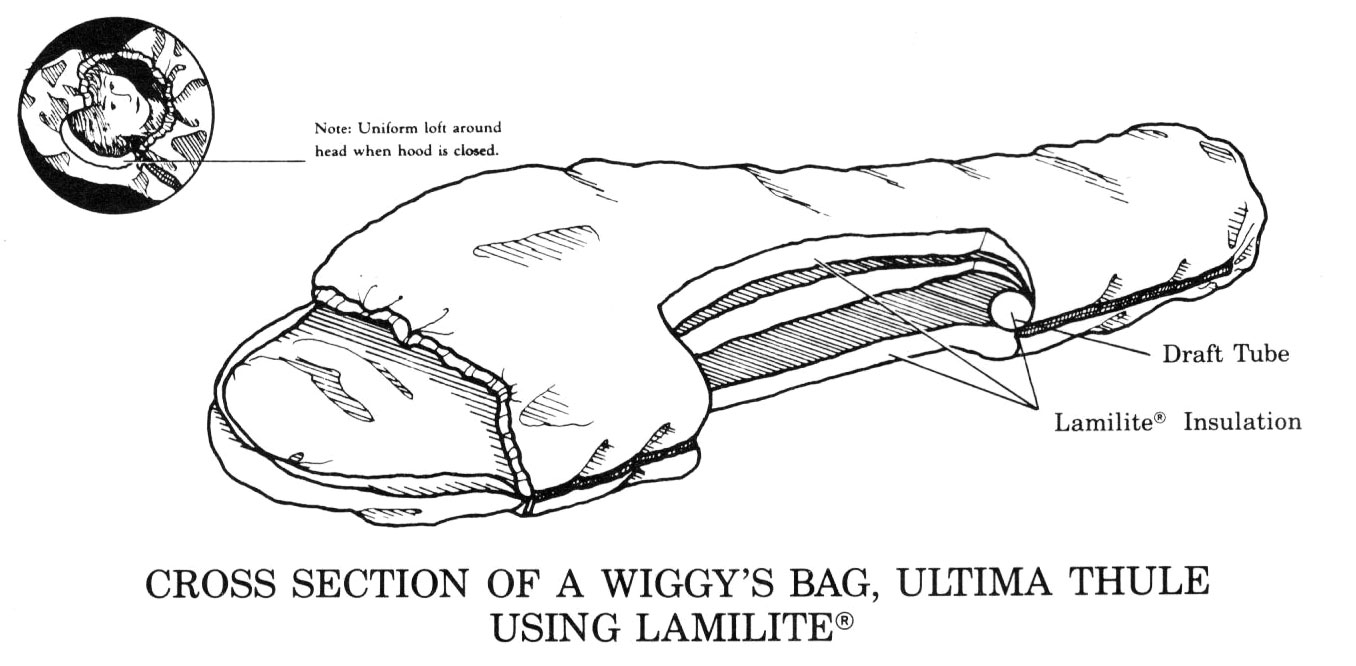

Lamilite is More Than the Fill Put Into Our Sleeping Bags

It is a combination of nylon fabric and fiberfill, two components that aid each other. The first part is visible. It is the 70-denier nylon commonly known as single ply taffeta. The 70 denier refers to the thickness of the yarn. The actual weave is 86 yarns in one direction and 104 yarns in the other, per square inch. The thickness of yarn is the optimum thickness to absorb body heat and quickly warm to your body temperature. The faster this warming occurs, the slower the rate of conductive heat loss from your body. The spaces between yarns in this construction allow the moisture your body produces to easily escape. It is irrelevant how dry a climate may be, your body gives off moisture. Therefore, it is important to allow this moisture easy exit. Water is extremely efficient at absorbing heat, so you always want to stay as dry as possible.

Our exclusive processing of the fiberfill laminates the nylon. The Lamilite is an unbounded, silicone-coated continuous filament fiber. This is inside and cannot be seen. The silicone coating gives the fiber two very desirable properties. The first is "antistatic" which allows the fibers to perpetually repel each other regardless of how tightly the fibers are packed against each other (such as compacting in a stuff sack). The loft always returns after removing our sleeping bag from the stuff sack. As an example, one of our Ultima Thule sleeping bags was compacted under 20 tons of pressure. It was blister packed in two poly bags the size of 14 1/2" x 9 1/2" x 2 3/4". After four days it was opened and in one hour, without assistance, 90% of its loft returned. A Lamilite insulated sleeping bag is the only synthetic bag ever put through this test that returned to its original loft. Not even a down bag will return to almost original, actually the down bags deteriorate when vacuum packed. It is for this reason that I guarantee my sleeping bags will never lose their loft. The Alaska National Guard, as part of their survival gear, uses the Ultima Thule. The bags are left in the vacuum package until needed. In 1994 the U.S. Navy authorized an Ultima Thule, vacuum packed, as the official survival bag carried by aircraft and ships. In addition, they determined that it actually performed at -35? F. The second benefit of the silicone treatment is in making the fiber HYDROPHOBIC. Hydrophobic comes from the word "hydrophobia," or fear of water. Water simply does not attach itself to the fiber. This is extremely important for the moisture leaving your body, passing through the spaces between the yarns and easily moving through the fiber. Also, it is extremely important for the moisture not to condense in the insulation. If this occurs when temperatures are below freezing, frost buildup can severely reduce the thickness of your insulation, as occurs with down, or the moisture simply freezes as in any other sleeping bag and adds weight.

Refer to the Steger Expedition to the North Pole in July 1986. They used 15 pound chopped staple fiberfill insulated bags that accumulated 35 pounds of ice. The fiberfill used in those bags was Quallofil, a fiber produced by DuPont Co. Even though the fiber is silicone treated, the fact that it was so densely packed in by the quilting prevented any flow of moisture while in a vapor state.

Lamilite Insulation is Very Drape-able

It is important the insulation of a sleeping bag drape around your body. The closer the insulation hugs your body, the less convective air movement occurs. The fiber pushes down on your body and the nylon lining touches your body. If the nylon did not touch your body, the heat from your body would be heating the air space directly above you and a convective air current would be generated. But with the nylon touching your body, it absorbs your heat quickly until it reaches your temperature. This heating action then slows, thereby reducing conductive heat loss.

Lamilite is Also Easily Laundered

In fact, Wiggy's is the only company that wants you to wash its products when they get dirty. When you go camping, you get dirty and so does your sleeping bag. After awhile, the dirt works its way into the insulation and combines with your body oil. This in turn causes the insulation to compact down or reduce loft, hence, loss of insulation. Therefore, it is important to wash your Wiggy's bag after each camping trip. Keeping the fiber clean will allow it to retain its original loft. Learn more about our care instructions. They are sewn into every bag.

Lamilite Insulation: Simply the Best!

All insulations, regardless of composition (synthetic fiber, down, wool, cotton) function exactly the same way. The thicker they are the better. As Gerry Cunningham once wrote "a ¼ inch jacket is only ¼ as warm as a 1-inch jacket.”

There are several factors that account for one insulator being better than another.

A. Loft for Weight - Since the mid 1960's, when camping became enormously popular, down has held the reputation for being the lightest weight insulator with the greatest amount of loft, for its weight. Considering what was available, it justified the #1 rating. In October of 1986, that changed. I developed the technology to use a synthetic fiber which had been used for 22 years as a pillow stuffing; an unbonded, silicone treated, continuous filament fiberfill. Ounce for ounce, it is approximately 25% loftier than all other synthetics, and—when used as insulation in sleeping bags—there is virtually no difference in loft or weight for each temperature range versus a down bag, when they are of equal size.

B. Compatibility - When comparing LAMILITE to down, the compactability factor is equal. No other synthetic insulator even comes close.

C. Effects from Moisture - Moisture and down are very compatible. Down absorbs moisture like a sponge. Using the so-called waterproof, breathable fabrics for the exterior will prevent water from getting to the down, but the real problem comes from the moisture the body emits. Once body moisture changes from vapor to liquid, it is absorbed by the down. Unless there is lots of sunshine to dry your sleeping bag, the lofting ability is decreased by the damp down. LAMILITE fiber not only doesn’t absorb moisture but allows the moisture, while in a vapor state, to pass through it easily and quickly. This is because of the silicone treatment which acts like a lubricant. Therefore, water in a vapor or liquid form does not affect the LAMILITE. It will always maintain its original loft.

D & E. Longevity to Perform/Ease of Care - I group these two subjects together since the care of each of the insulators is vital to its overall performance. Down must be stored a certain way, laundered a certain way and, since it is a natural product, will deteriorate over a period of time. The care given to down will determine its longevity.

LAMILITE, on the other hand, is an easy care product. A LAMILITE sleeping bag (WIGGY'S BAG) is launderable in warm to cool water and dried at a low temperature setting in standard machines. A good practice is to launder a LAMILITE bag whenever it gets dirty (generally after every use). LAMILITE is so resilient, it can be stuffed in its stuff sack for storage. Considering the loft is long-lasting, it will always perform.

You may have noticed I have not mentioned any other form of synthetic insulation still used for sleeping bags. My reason is simple. None of the other synthetics have been comparable to down, and LAMILITE surpasses it.